COURTESY OF MCCONKEY COMPANY

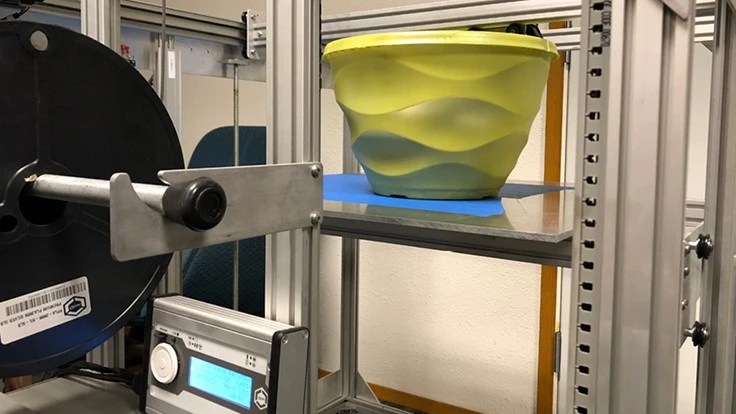

About four years ago, McConkey Company started using 3D printer technology to develop prototypes for plastic containers and landscape packs. They have three 3D printers, the largest being capable of printing an object with a volume of up to 8 cubic feet. This has provided several benefits, including making innovation faster and more affordable. Derek Moeller, president of McConkey, describes how the technology works, how it has changed business and the benefits for growers and retailers.

Q: You’ve been using 3D printers for about four years. What inspired you to invest in this technology?

A: What it came down to is that our customers, growers,

It became a challenge because the conventional way of doing things was to show people a 2D line drawing. That is very useful when you’re designing something when you already know what dimensions it has to be and you already know the functional aspect of it. But it doesn’t tell you much about how it’s going to work in your operation, how it’s going to look with a plant in it, if it will look attractive, and if it has a nice geometry and shape to it. In order to figure that out, we had to have a way of representing these objects, in a way that you could touch and feel and run through a machine without building a whole mold.

Q: What are the challenges of the

So, really the driver behind the 3D printing is all about risk mitigation and innovation, and it dramatically lowers the risk of innovation, accelerating the rate of innovation.

Q: How does 3D printing solve those challenges?

A: It allows you to do iterations. You get the first prototype, and you can get some feedback about how you’d like it to be different and what changes can be done. Previously, because you’d have to build a mold, and then, when you’d want to change, you’d have to build another mold, you could have years and years go by to get to [another] version of something. Whereas now we can do version one, two, three and four within 30 days and not have it be that expensive. A lot of innovation anywhere, including the greenhouse business, is iterative. It’s trying something, seeing how it works, finding tweaks you want to make to it and going from there.

COURTESY OF MCCONKEY COMPANY

Q: How long does it take to print?

A: It is dependent on size and the amount of detail that is there. Generally within a number of hours. You go from two to three months to build a mold and have the first sample down to three to four hours to see the first sample.

Q: You showcased a fun, 3D printed container design at Cultivate a few years ago, and it ended up becoming a product.

A: That particular one was kind of interesting because that design was never something that we really intended to make a pot out of. [A grower based in Canada] saw the prototype at Cultivate’15. It was something kind of crazy that our design team came up with and decided to 3D print because it looks fun. We didn’t look at how we’d actually be able to make it at all. One of our customers saw it [at the show] and said, “I love it. I want this for my hanging basket.” We told him, “You don’t understand, we wouldn’t design this. It’s not manufacturable. This is just an object of fun, really.” But he said he really liked it. We went through the manufacturability process and engineering and came up with a product that had a lot of characteristics of that product but as a big 12-inch hanging basket that would be able to be made with standard industrial equipment. It’s one of the most innovative and interesting hanging baskets that I’ve seen on the market. It’s just a gorgeous design, and I can say with certainty that that item would have never come to market without the ability to play around with the 3D printer and then have one of our customers see it, and [ask us] to turn that into a real product and buy it. It went to market in 2017, and we’ve provided regional exclusivity to that customer for that area for the duration of the program.

Q: Because it was a unique shape, was the process to create the actual product challenging?

A: We had to change how the mold would be ejected out of the ejection mold, there was a lot of geometry we had to tweak. Our designer was working on that for weeks in coordination with the engineering team to turn that into a product that could actually be injection molded and would actually stack on

Q: What else have you developed using 3D printing technology?

A: The other interesting area is more on the functional side. We’ve been experimenting a lot with enhanced retail solutions for tags. The idea here is to be able to marry a landscaping pack with a tag with UPC information on it. People don’t want to bring in their containers with labels on them, because as a

Q: Are these pots and landscape packs being used now or are they still in development?

A: People are taking test quantities this spring for a full launch in 2019. One customer is doing a full-scale launch, and they are moving along with production.

Q: How do retailers benefit from this?

A: The advantage for retailers is that they can now

So retailers get much more data, and ultimately they are going to be able to tell you what inventory they have at retail. They get to put the price point on a tag, and research has shown that consumers prefer to have that pricing information on the product. They also get consistency in the retail display, a nice tag that’s always in the same

Explore the January 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Garden Center

- AmericanHort urges exclusion of sphagnum peat moss from proposed Canadian tariff

- VIDEO: Garden Center's 2024 State of the Industry Report

- The Growth Industry Episode 2: Emily Showalter on how Willoway Nurseries transformed its business

- Farwest Show calls for 2025 New Varieties Showcase entries

- Oregon Nurseries Hall of Fame member Jack Bigej passes away

- Everde Growers files for Chapter 11 bankruptcy

- DCA Outdoor files for Chapter 11 bankruptcy

- This Florida garden center's busiest days are in the fall, not spring. Find out how they do it